CAPABILITY

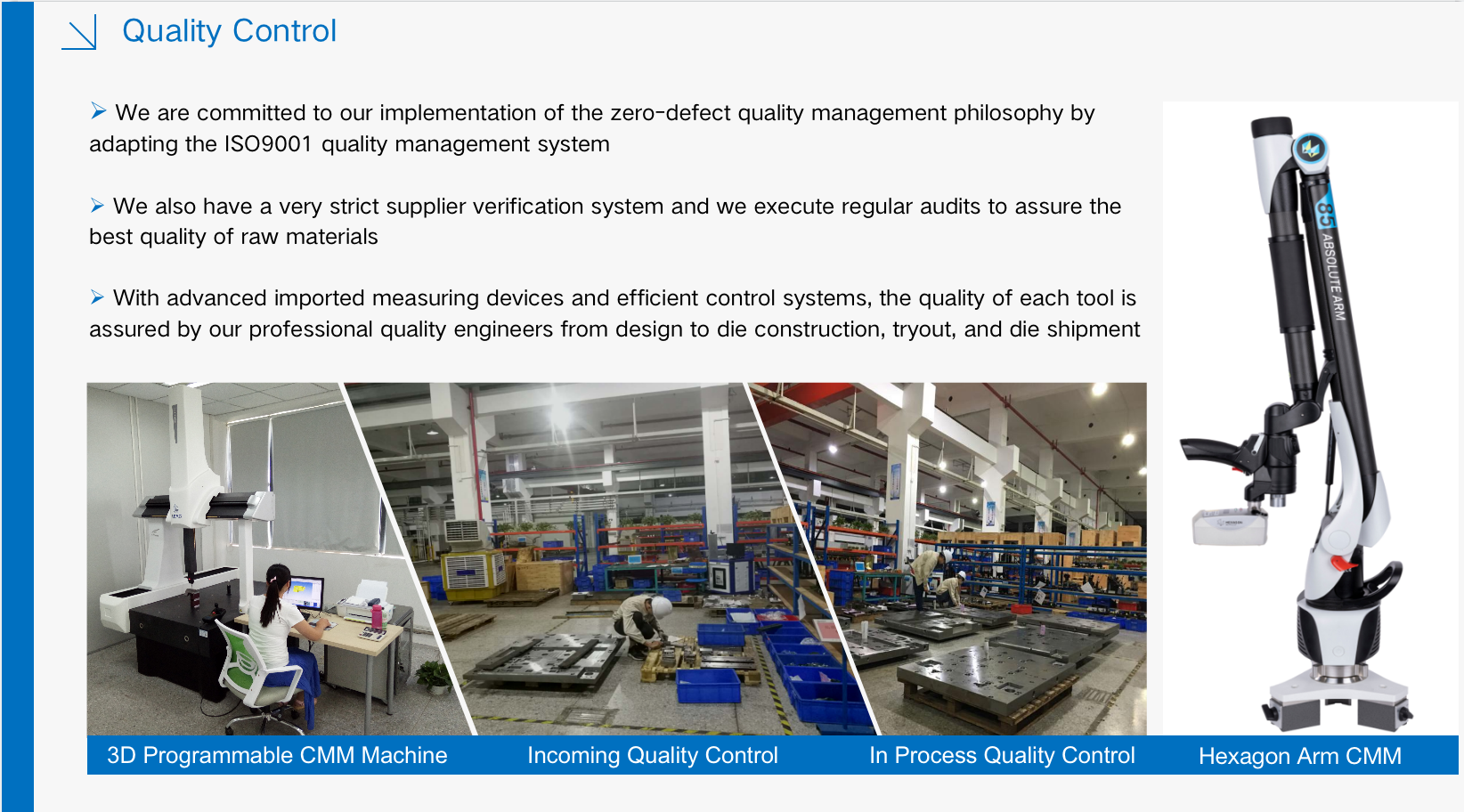

Quality Control

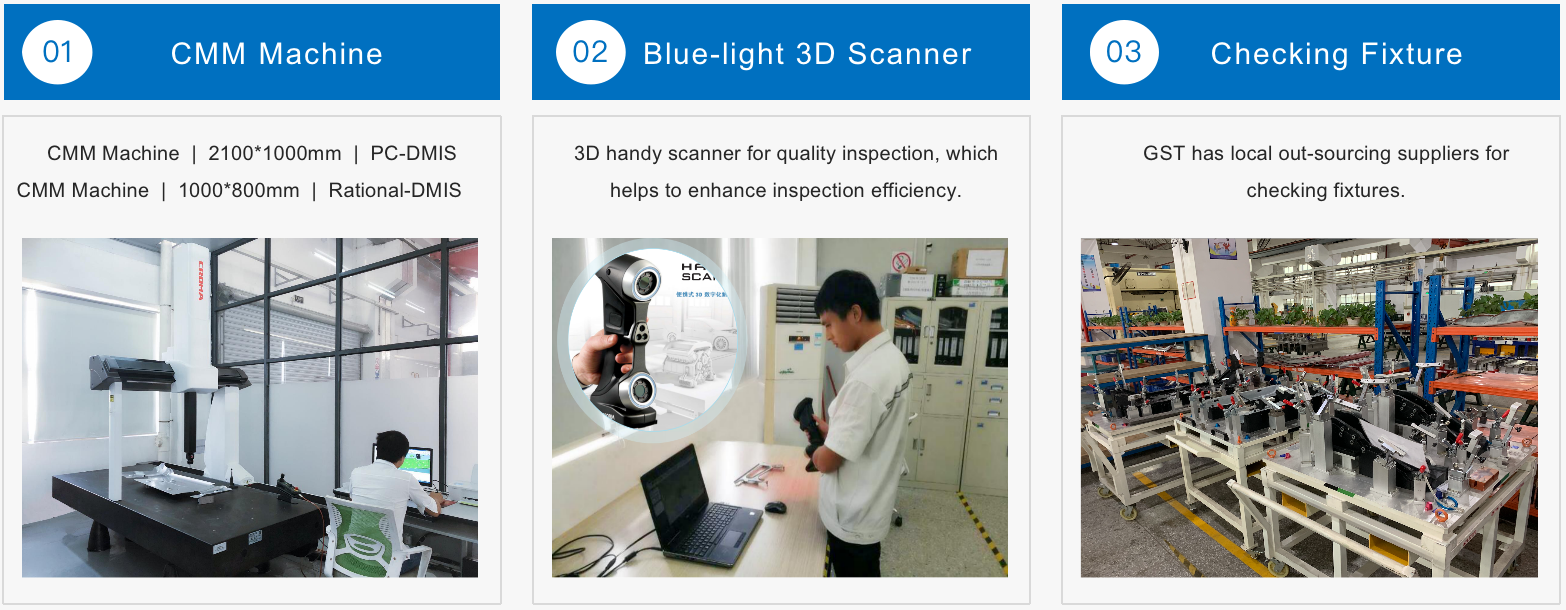

Quality is the soul of the brand, precision is the basis of the business. In order to ensure precise quality, GST especially sets up a quality department, which is equipped with 3D measuring instrument, 3D handy scanner projector, height measuring instrument, sclerometer and other precision measuring tools. It strictly implements the ISO 9001 quality system requirements to precisely control all tools and stamping parts. QC inspector precisely test and adequately document the appearance, dimension and hardness of all components to ensure product quality. And then they will record the result to quality control system.

We are committed to our implementation of the zero-defect quality management philosophy. This quality sense has been implemented on each process. We also have very strict supplier verification system, and we execute the regular audit to assure the best quality raw materials. Only qualified suppliers can be our cooperators.

With advanced imported measuring devices and efficient control system, the quality of each tool is assured by our professional quality engineers from design to construction to sample to pre-shipment.

1. Strip Layout & Tool Design Control

2. Tool Steel Hardness Inspection

3. Cutting & Forming Steel Dimension Inspection

4. Tool Pre-Assembly Inspection

5. Samples CMM Inspection Report

6. Tool Buyoff Validation Report

7. Pre-Shipment Final Inspection

8. Export Tool Package Inspection